Views: 0 Author: Site Editor Publish Time: 2025-05-23 Origin: Site

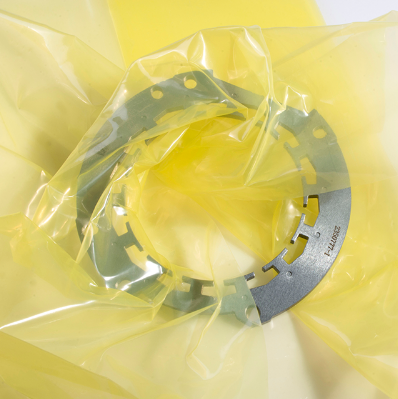

In the highly regulated world of medical device manufacturing and sterile processing, packaging plays a pivotal role—not only in maintaining sterility but also in protecting expensive instruments from corrosion. From surgical scalpels and orthopedic implants to delicate endoscopes and reusable trays, the integrity of medical equipment is paramount. Corrosion not only compromises device performance but also raises patient safety concerns and inflates hospital operating costs through instrument downtime, rework, or replacement.

Traditional anti-rust wrapping methods—such as oil-based coatings and desiccant packs—often conflict with sterilization requirements or introduce contaminants that must be removed before clinical use. Vapor Corrosion Inhibitor (VCI) films represent a groundbreaking solution that simultaneously ensures sterile barrier performance and long-term corrosion protection. By embedding micro-encapsulated corrosion inhibitors within a multi-layer polymer laminate, VCI films release protective vapors throughout the packaged environment without affecting sterility or leaving residues.

Medical device packaging must satisfy three critical and sometimes conflicting requirements:

Sterile Barrier Integrity

Packages must maintain a sterile environment from the point of sterilization—whether by steam, ethylene oxide (EO), or gamma irradiation—through to the time of clinical use. Any breach in the barrier or contaminant introduction can lead to infection risks.

Corrosion Protection

Many medical instruments are made of stainless steel, titanium alloys, or other metals that can corrode when exposed to moisture, residual cleaning chemicals, or electrolyte vapors. Corrosion not only degrades device performance but also complicates cleaning validation and may lead to instrument failures during critical procedures.

Biocompatibility and Cleanroom Compatibility

Packaging materials must pass stringent extractables and leachables testing to ensure they do not shed particulates or leach harmful chemicals under sterilization conditions.

Marrying these requirements in a single package material is no small feat. Traditional VCI powders or oil-infused wraps provide corrosion inhibition but are incompatible with autoclaves, gas sterilizers, or irradiation processes. Conversely, medical-grade barrier films excel in sterile performance but lack active corrosion protection. VCI films overcome this dilemma by integrating inhibitor technology into the polymer itself, maintaining pristine barrier attributes while releasing corrosion-preventing vapor-phase molecules on demand.

Many medical device packagers have historically experimented with simple anti-rust wraps—grease-impregnated paper, oil-coated films, or desiccant pouches—to protect instruments from moisture-induced oxidation. However, these approaches falter when subjected to the high heat (121–134 °C), pressures (up to 3 bar), and saturated steam environment of a standard autoclave cycle:

Oil and Grease Breakdown

High temperatures cause grease-based coatings to thin or migrate, leading to uneven distribution and potential contamination of packaging seals and trays. Leaked oils compromise pack integrity and require additional cleaning steps post-sterilization.

Paper or Non-Barrier Films

Simple paper wraps may allow steam penetration but lack the multi-layer barrier structure to retain corrosion inhibitors or maintain a dry microenvironment once the autoclave cycle ends. After sterilization, moisture trapped within the package accelerates corrosion.

Desiccants Alone Are Insufficient

Desiccant pouches can absorb moisture but do nothing to neutralize corrosive vapors or passivating metal surfaces. Once saturated, they no longer protect, and replacing them adds complexity and cost.

Given these shortcomings, packagers need a film that withstands autoclave temperatures and pressures without losing corrosion-inhibiting function or jeopardizing sterile barrier performance. VCI films, with their stable polymer matrices and micro-encapsulated inhibitor reservoirs, deliver exactly that resilience.

At the heart of VCI film technology lies a multi-layer, co-extruded polymer laminate designed to deliver both robust barrier performance and controlled inhibitor release. Typical layer architecture includes:

Outer Protective Layer

A tough, abrasion-resistant polyethylene (PE) or polypropylene (PP) surface that withstands handling, puncture, and moisture ingress during transport and storage.

Barrier Layer

A high-density polyethylene (HDPE) or EVOH (ethylene vinyl alcohol) layer that blocks oxygen, water vapor, and airborne contaminants—key to maintaining sterility and preventing external corrosion agents from entering.

Inhibitor-Loaded Carrier Layer

A polymer blend containing micronized organic VCI compounds uniformly dispersed within the matrix. This layer slowly releases inhibitors in vapor form without compromising mechanical integrity.

Inner Heat-Seal Layer

A low-melting PE or PP inner layer that ensures reliable peelable or peel-and-reseal packaging, critical for maintaining sterile barrier capabilities.

By co-extruding these layers in a single process, manufacturers create a film less than 100 μm thick that offers tear strength, puncture resistance, and barrier properties meeting ISO 11607 standards for sterile packaging.

Unlike surface-applied inhibitors that risk uneven coverage, VCI films rely on micro-encapsulation of corrosion-inhibiting chemicals—such as benzotriazole derivatives, amine carboxylates, or triazoles—directly within the carrier layer. Key benefits include:

Consistent Vapor Pressure

The homogenous dispersion ensures a steady, controlled release of inhibitor vapors over the film’s service life (typically 12–24 months), even under fluctuating temperature and humidity.

Invisible Protection

Since the inhibitors exist in vapor form, no oily residues or visible films remain on instrument surfaces. This means no post-sterilization cleaning is required.

Self-Replenishing Shield

If the passivating layer on a metal surface is physically disturbed during handling, fresh inhibitor vapor automatically re-adsorbs to restore protection.

This advanced chemistry, combined with robust polymer scaffolding, creates a package that is both a sterile barrier and an active corrosion prevention system.

Ethylene oxide sterilization operates at low temperatures (37–63 °C) and requires extended aeration to remove residual EO. VCI films are engineered to withstand EO exposure without significant inhibitor loss or chemical modification:

Minimal Off-Gassing

Studies show that inhibitor retention remains above 90% after a standard EO cycle (four hours exposure followed by 12–48 hours aeration), ensuring that protective efficacy is maintained post-sterilization.

Barrier to Residual EO

The multi-layer structure reduces EO permeation back into the package interior during aeration, limiting the risk of EO residues interacting with medical instruments.

Gamma sterilization (typically 25–35 kGy) can induce polymer cross-linking or chain scission, potentially affecting film tensile strength and inhibitor release:

Radiation-Resistant Polymers

VCI films employ radiation-stabilized polyethylenes and proprietary antioxidants in the carrier layer to mitigate polymer degradation.

Preserved Inhibitor Function

Post-irradiation testing reveals that vapor-phase inhibition capacity remains within 5% of pre-irradiation levels, confirming that active molecules are not structurally compromised by high-energy photons.

Steam sterilization poses the greatest challenge due to high heat, moisture, and pressure. VCI films rise to meet these conditions:

Thermal Stability

High melting-point polyolefin layers maintain structural integrity at 134 °C. Film elongation and tensile strength remain within acceptable ranges after multiple autoclave cycles.

Moisture Barrier

While steam enters the package during sterilization, the barrier layer prevents prolonged moisture retention. Once the cycle ends, residual moisture is expelled through controlled venting, and the microporous seal layer allows any remaining steam to escape without compromising barrier function.

Collectively, these compatibilities ensure that VCI films can be seamlessly integrated into existing medical device sterilization workflows without additional process steps.

Different sterilization methods place unique demands on both polymers and inhibitors. To fine-tune VCI films, manufacturers may:

Tailor Inhibitor Type and Loading

Select inhibitors with higher thermal stability for autoclave-only applications, or use fast-off-gassing compounds for short EO cycles.

Incorporate Radical Scavengers

Add antioxidants like hindered phenols to further protect the polymer matrix during gamma or e-beam irradiation.

Layer Thickness Variation

Increase barrier layer thickness in films destined for multiple autoclave cycles, or boost carrier layer concentration when long-term storage is required.

Beyond film chemistry, package design ensures that VCI benefits translate to real-world performance:

Seal Construction

Optimize heat-seal dwell times and temperatures to achieve uniform, peelable seals that withstand sterilization pressures yet provide easy, controlled opening in the operating room.

Peel Force Calibration

Balance easy peelability (to protect sterile contents) with sufficient seal strength (to prevent inadvertent opening during transport).

Indicator Integration

Incorporate chemical indicators that confirm exposure to sterilization parameters without interfering with VCI efficacy. This dual-indicator approach streamlines quality control in sterile processing departments.

Package Geometry

Design pouches and trays to ensure even inhibitor vapor distribution—avoiding large voids or overly compact assemblies that could impede vapor flow.

Through iterative prototyping and validation, medical device packagers can develop VCI-film based sterile packs that meet both regulatory and operational needs.

Sterile corrosion protection with VCI film represents a paradigm shift in medical device packaging. By embedding corrosion inhibitors directly into the polymer structure, these films deliver invisible, self-replenishing vapor-phase protection while maintaining full compatibility with EO, gamma, and steam sterilization processes. Hospitals and device manufacturers benefit from:

Enhanced Patient Safety: Zero risk of residual oils or particulates that could compromise sterile fields.

Streamlined Workflows: Elimination of degreasing or cleaning steps reduces labor costs and turnaround times in sterile processing departments.

Instrument Longevity: Proven resistance to moisture-induced oxidation extends the usable life of high-value instruments.

Regulatory Confidence: Films engineered and tested to ISO 11607, CFR Title 21, and international sterilization standards.

For medical device innovators ready to embrace this new trend, collaboration with a trusted materials partner is key. VCI EP NEW MATERIALS (SHANGHAI) CO., LTD. specializes in advanced VCI film formulations tailored to the rigorous demands of sterile medical packaging. Visit www.vcipluspacking.com to explore our full range of medical-grade VCI films, download detailed technical data sheets, and review independent compatibility studies. Our application engineers are on hand to offer personalized consultations, pilot packaging trials, and rapid prototyping to ensure your next generation of medical devices ships corrosion-free and ready for clinical use.

Partner with VCI EP today—because in medical device packaging, sterile protection and corrosion prevention should never be mutually exclusive.